Construction & Installation

Like our customers, Michels Trenchless, Inc. believes safe, unobtrusive underground construction and rehabilitation is essential to our nation’s infrastructure. That’s why we have perfected an array of trenchless methods to build and rehabilitate pipelines and utilities in places where open-trench installations would not be feasible.

Discover Michels Trenchless new installation and pipeline rehabilitation solutions.

Horizontal Directional Drilling

Michels Trenchless has decades of experience extending the limits of horizontal directional drilling (HDD) by working together, knowing what has already been accomplished, and taking existing techniques to the next level. In the hands of our skilled operators, these machines can place pipes up to 60 inches in diameter to distances of more than 15,000 feet.

HDD is used for installing utility and product lines under waterways, existing utilities, and underground structures. In the hands of our skilled professionals, our powerful rigs place liquid, gas, cable, and conductor lines and pipe up to 60 inches in diameter to distances of more than 15,000 feet. Since 1988, we have been mastering HDD to place pipe substantially deeper than conventional trench construction, ensuring adequate cover and environmental surety.

- Provide

- Alternative delivery, project design and engineering

- Custom fabricated

- large, specialized equipment

- Capable of

- 1.8 million pounds of drilling thrust & pulling power

Marine Experience

Michels has over 30 years of marine shore approaches and has completed over 50 deep-sea horizontal directional drills.

Direct Pipe®

Michels Trenchless is a world leader in Direct Pipe® installations. By combining horizontal directional drilling (HDD) with steerable microtunneling techniques, Direct Pipe® can install a prefabricated liquid, gas, or product pipe or casing with a continuously supported borehole. Direct Pipe® is particularly suited for crossings under water bodies, levees, rail tracks, roads, and underground utilities and can be installed in unfavorable ground conditions with ease.

Unlike HDD, Direct Pipe® equipment is primarily located on one side of the project, making it ideal for crossings with small footprints, wet retrievals, in urban areas, and even under international borders.

- One-pass

- Pipe Installation

- Distances more than

- 4,000 feet

- Diameters between

- 30 & 60 inches

History in the Making

Michels completed North America’s first international border crossing using the Direct Pipe method in 2014. The 48-inch pipeline started its crossing in Texas and emerged 2,460 feet later in Tamaulipas, Mexico.

Tunneling

Michels Trenchless is a go-to contractor for the most challenging tunneling projects, from the largest metropolises to remote regions on land and under water. We set the bar for rapid performance, environmental protection, and safety when constructing tunnels for pipelines, water mains, and storm and sanitary sewer lines.

Our comprehensive pre-planning process includes working with our customers to develop methods for building safe, reliable tunnels—including the first tunnel ever built under San Francisco Bay.

Our techniques include:

- Earth Pressure Balance Tunnel Boring Machines (TBM)

- Hard rock TBM

- Conventional drill blast tunneling

- Sequential Excavation Methods (SEM)

- remote-controlled tunneling systems

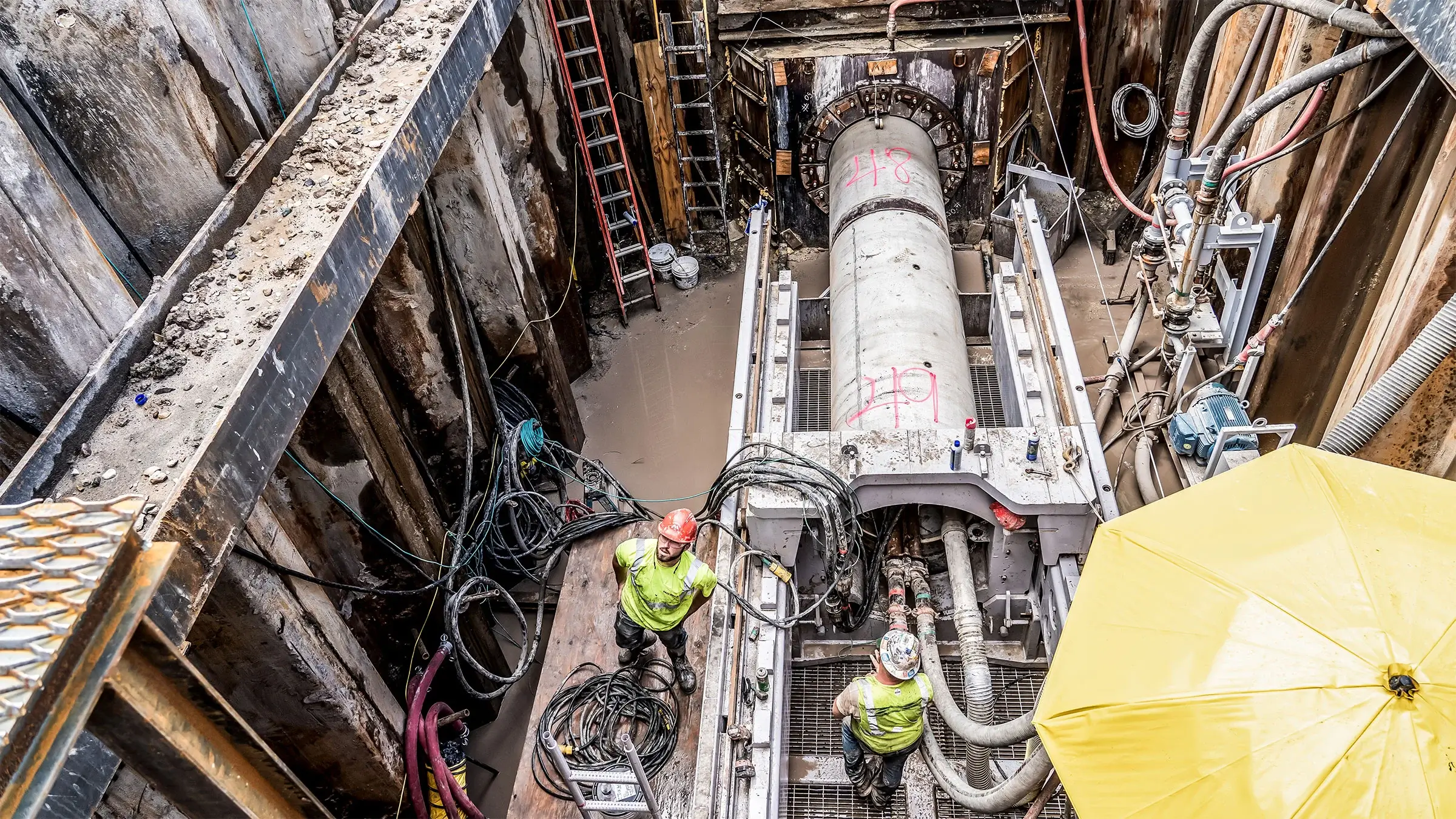

Microtunneling

Michels Trenchless uses microtunneling to mine and build tunnels in all soil conditions. The combination of a remotely controlled, guided MTBM, casing pipe, and pipe jacking operation provides for continuous support. Microtunneling is effective for construction under roadways, waterways, areas with high groundwater tables, and other challenging situations.

Because microtunneling is a closed-face system, it can be launched from a shaft on land to a predetermined underwater endpoint. After a bulkhead is attached, divers disconnect and lift the MTBM to the surface. Michels Trenchless has successfully completed dozens of these wet retrievals.

- Diameters up to

- 10 feet

- Intake Diameters range up to

- 82-inches

- Successfully completing wet retrievals since

- 1993

Pipe Assist

Even the most powerful HDD rigs occasionally need a helping hand. Michels Trenchless performs pipe assist by using a Direct Pipe® thruster with up to 750 tons of force to support an HDD rig during pullback of a large, heavy pipe string.

When not needed, the thruster sits at the ready, fitted concentrically around the pipe. It can be quickly engaged when needed to propel a pipe that has become locked, immobilized, or needs a little assistance.

Auger Boring

Michels Trenchless uses auger boring to install utility lines within industry line and grade tolerances in a variety of soil conditions. A standard trenchless method with highly technical variables, auger boring allows a casing pipe to be jacked into place under railroads, roads, runways, property, other utilities or environmentally sensitive areas with minimal disruption to the public.

When extreme precision or long distances are required, Michels Trenchless completes guided auger boring by combining traditional auger boring with pilot tube systems or our HDD guidance systems.

Innovation In Action

We completed the first pilot hole intersect project in North America and have completed more than 250 since then.

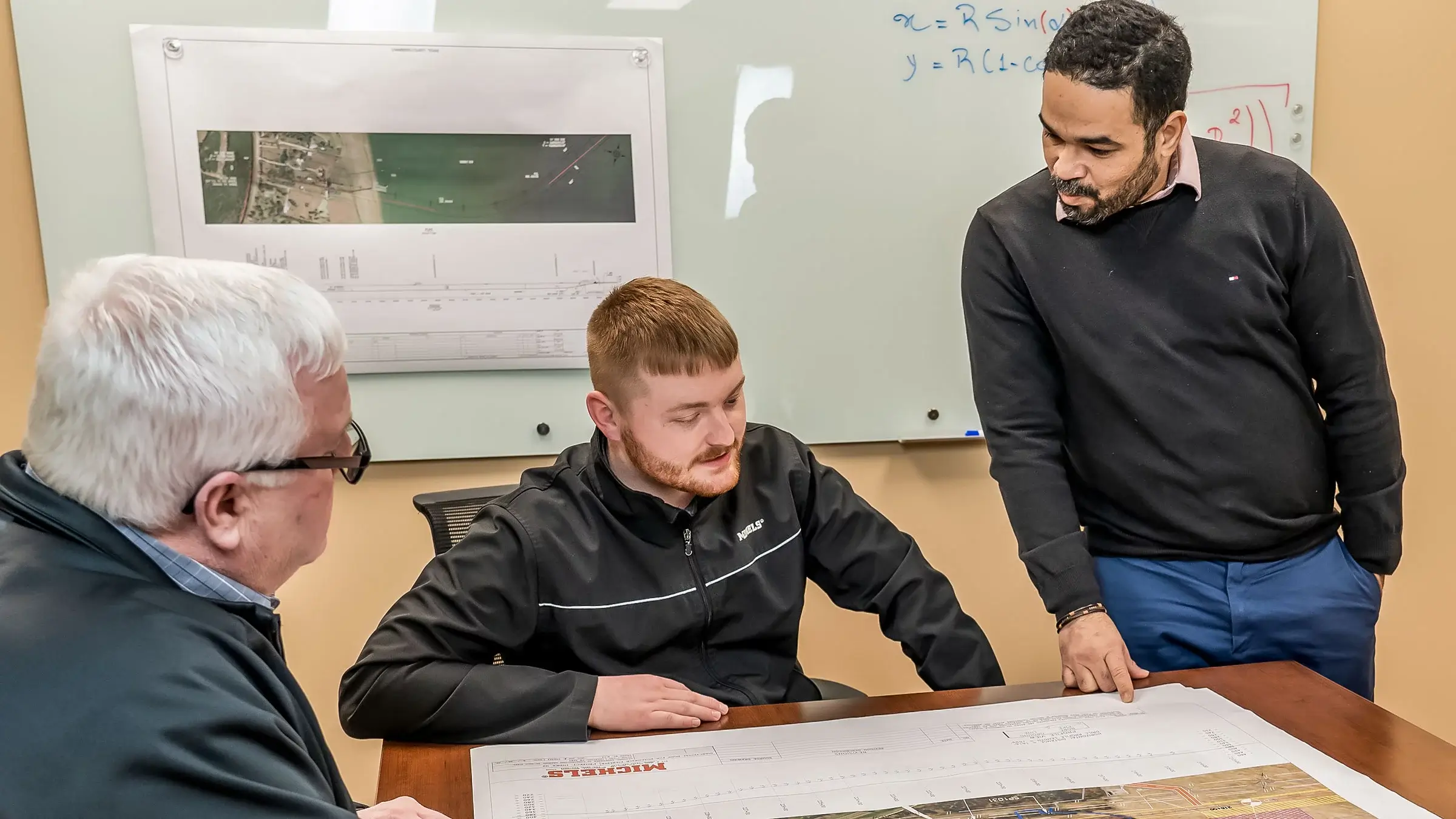

Preconstruction Services

Clear communication and collaboration between a contractor, owner, and design engineer from preconstruction through closeout ensures an understanding of project goals and expected outcomes. Using an alternative delivery model offers many benefits including constructability review and recommendations, improved risk management, project coordination and innovation.

Options beyond the conventional design-bid-build method can save time and money, require less owner resources, and deliver turnkey projects. We have been delivering early contractor involvement (ECI) and design-build models for more than a decade.

Offshore Wind and Renewables

Michels Trenchless combines our expertise with specialties in the Michels Family of Companies to offer complete design and construction of all critical components of offshore wind and renewables projects.

We use our decades of experience with Horizontal Directional Drilling, Direct Pipe and Microtunneling to understand our customers’ goals and consider the constructability and probability for success of each trenchless option. After a method has been selected, we use the combined abilities, expertise and assets of the Michels Family of Companies to develop plans and complete offshore, landfall and onshore scopes of work to connect an offshore energy project with the existing energy grid.

- Coastal Virginia Offshore Wind

- Trenchless Overview

- Trenchless New Installation

- Trenchless Rehabilitation

Contact Us

Thank you for taking time to learn more about who we are and what we do. If you need additional information or are in need of a solution not addressed on these pages, please submit a message with your contact information.