River Avenue Force Main CIPP

Michels Trenchless, Inc. performed an emergency repair of a sewer main that had ruptured in multiple Connecticut locations. Approximately 3,000 feet of a 14-inch diameter ductile iron force main sewer was rehabilitated using pressure pipe cured-in-place pipe (CIPP) liner.

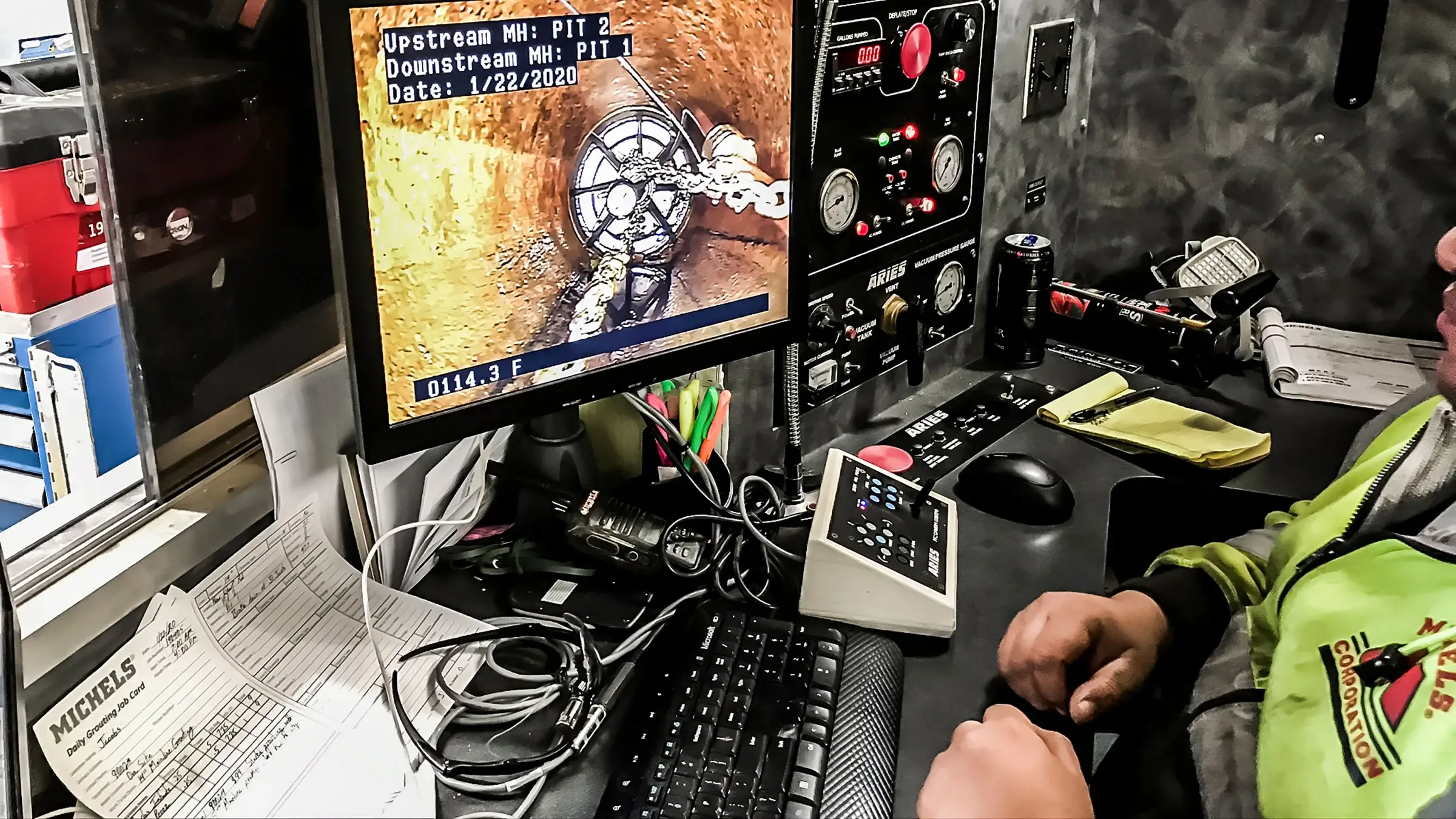

Upon cleaning and using CCTV in the main sewer, it was discovered a 770-foot segment of pipe was in extremely poor condition. Due to the pipe segment’s proximity to the Thames River and the local topography, the pipe was below the water table and subject to heavy infiltration.

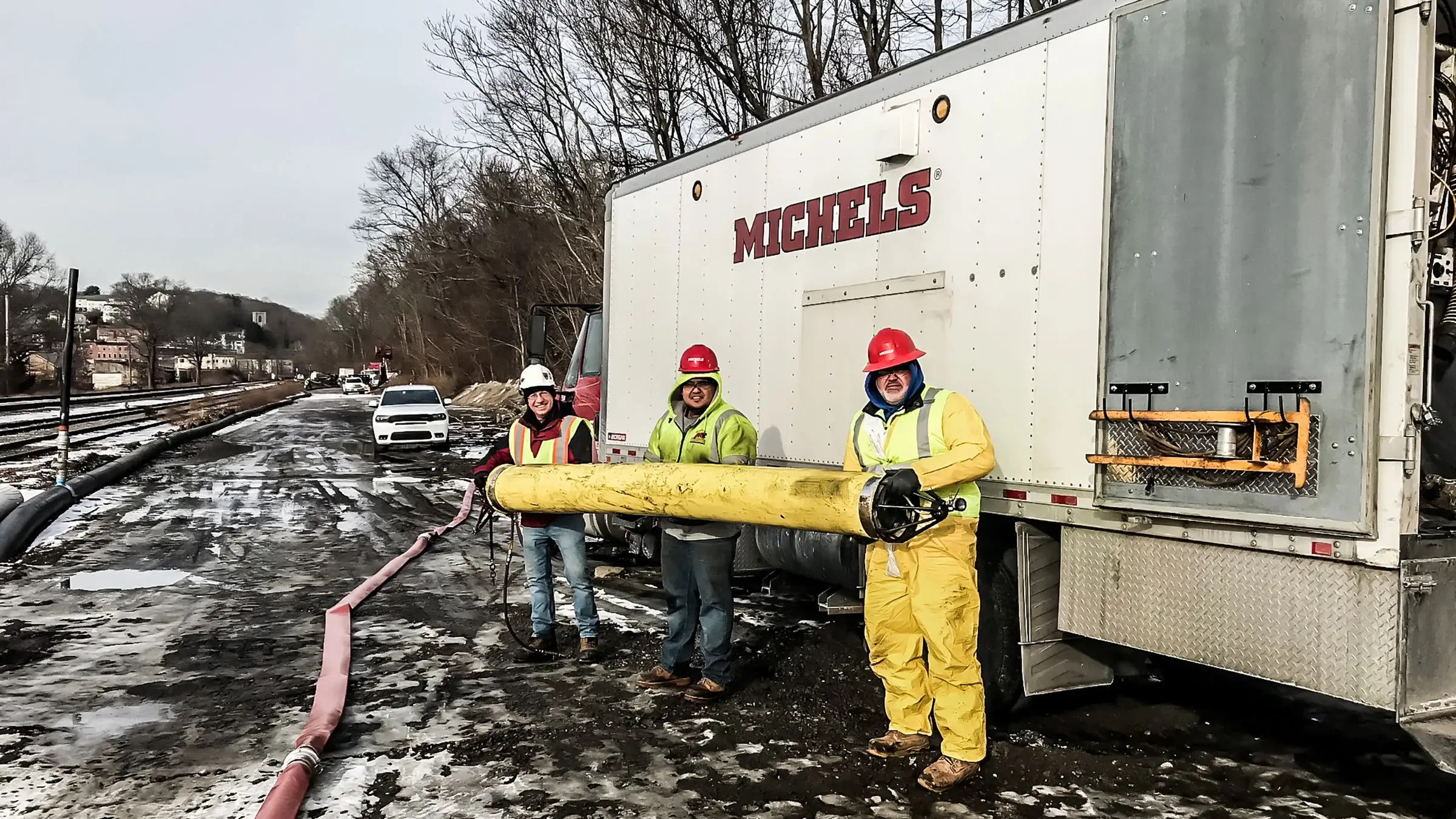

To successfully install the liner, the infiltration needed to be stopped. The pipe was too close to an active rail line to install dewatering wells. The average length of a grout packer is typically 1.5-2 feet long, but Michels and an equipment manufacturer worked together to custom build a 9-foot-long grout packer to control infiltration. Grout packers of this length are rare in the industry. Additionally, it was built with special material on the bladders to seal the heavily damaged pipe.

After Michels successfully sealed the sewer main with chemical grout, we installed a specially designed pressure pipe, glass-reinforced felt liner. This liner produced a flex modulus of over 1 million psi, allowing for a thinner CIPP composite to gain maximum flow through the force main.